1. Why coated cans?

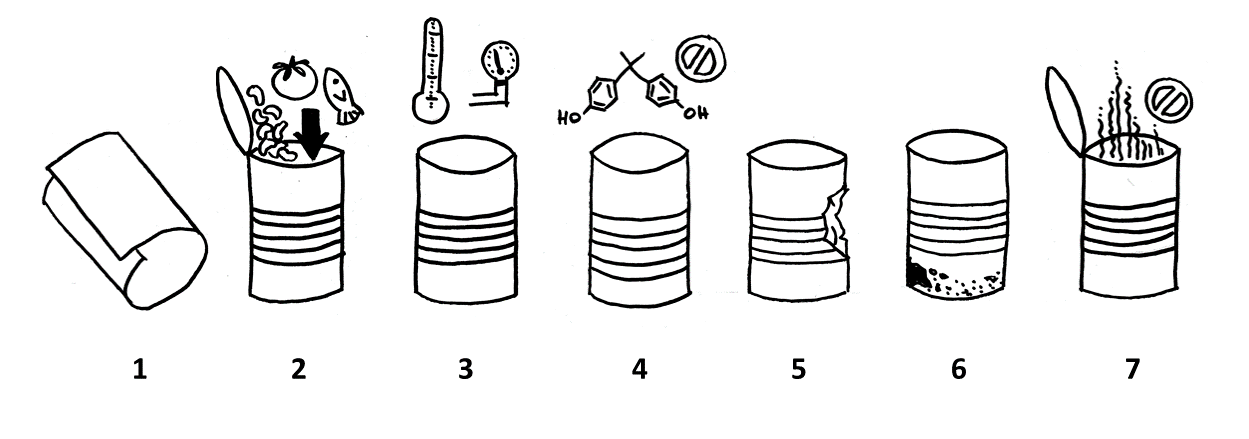

Food and beverage cans preserve the taste and nutritional values of their filling for up to several years. As a consequence of such long storage times, the interactions between the packaging and the food need to be minimized. Cans are typically coated with an organic layer that protects the integrity of the can from effects of the food and prevents chemical reactions between the can’s metal and the food. To fulfill the technical and legal requirements, can coatings should withstand the production and sterilization processes (1, 3), be universally applicable for all food and beverage types (2), prevent chemical migration into food in quantities that endanger human health (4), adhere to the can even after non-intentional deformation (5), resist aggressive food types and protect the metal of the cans (6), and preserve the food and maintain its organoleptic properties over several years (7).

2. Can production and market data

Cans are made of three different materials: aluminum, tin-coated steel (tinplate) and electrolytic chromium coated steel (ECCS). Can bodies are either formed as 3-piece welded cans (3PC), 2-piece drawn and redrawn (DRD) cans or as 2-piece drawn and ironed (D&I) cans. Independently of the material and the production process, most cans are coated internally and externally with films of 1 to 10 µm thickness. Coatings are usually applied to both sides of planar metal sheets or coils by roller coating before the cans are formed. Alternatively, coatings are sprayed on preformed cans. Tin cans are used without internal coatings for light colored, acidic juices and fruits (e.g. pineapple, pears, peaches), because tin is more easily oxidized than the food, thus preventing darkening and flavor changes caused by oxidation of the fruits. Food cans are usually pressure-sterilized with the exact conditions depending on the food type. However, beverage cans may be pasteurized or sterilized in the sealed cans or filled under aseptic conditions.

More than 300 billion beverage cans are produced globally each year. In 2014, 90% of the beverage cans were made of aluminum; the remaining 10% consisted of steel. Furthermore, it was estimated that 75 billion food cans were sold globally in 2011. In 2013, about US $30 billion and US $9 billion were globally earned with beverage and food cans, respectively. In 2011, the global production capacity of can coatings was estimated to be 800’000 metric tons, which corresponds to a market value of €2.8 billion.

3. Coatings: properties and alternatives

Many different can coatings are commercially available, but most of them are based on a limited number of chemicals functionalities (Table). Coatings contain different additives, e.g. agents to increase surface slipping as well as abrasion and scratch resistance of can coatings, lubricants, anti-foaming agents, adhesives, scavengers for hydrochloric acids, and pigments.

Epoxy-based coatings have the highest market share of more than 90%. However, can manufacturers and food companies have started to replace BPA-based epoxy coatings by alternatives as a consequence of toxicological evidence, public discussions, and recent regulatory decisions. Acrylic and polyester coatings are currently used as first generation alternatives to epoxy coatings and, more recently, polyolefin and non-BPA epoxy coatings were developed. Further inventions include BPA capturing systems and top coatings. Most of these alternative coatings are more expensive than epoxy coatings and may not display the same array of characteristics with respect to their stability and universal applicability yet.

Epoxy coatings

In the 1950s, epoxy resins were introduced as coatings for aluminum and steel cans. Their stability, protective function, and technical properties made them the most commonly used coating material. Most epoxy coatings are synthesized from bisphenol A (BPA, CAS 80-05-7) and epichlorohydrin forming bisphenol A-diglycidyl ether epoxy resins. Many different blends of epoxy coatings were developed with epoxy-phenolic coatings being the most important subgroup. Other blended resins are e.g. epoxy amines, acrylates, and anhydrides.

Oleoresins

First can coatings were made of oleoresins, which are mixtures of oil and resin extracted from plants. Oleoresins are rather flexible and easily applied, but do not adhere well to metal surfaces, have a limited corrosion resistance, and need long curing times. Furthermore, they may change the organoleptic properties of food.

Vinyl

Vinyl coatings are synthesized from vinyl chloride and vinyl acetate. They are highly flexible and stable under acidic and alkaline conditions, but they do not adhere well on metal and do not withstand at high temperatures. Vinyl coatings need plasticizers and stabilizers and are often blended with other resins. Vinyl organosols are prepared from suspensions of resin in organic solvent. Organosols offer comparably higher chemical resistance, thermal stability, and adhesion properties than vinyl coatings.

Phenolic

Phenolic resins are composed of phenols and aldehydes. They are highly corrosion resistant and protect cans from sulfide staining. Phenolics have low flexibility, do not adhere well to metal, and may change the odor and flavor of foods. They are applied as coatings for drums and pails, but unblended phenolic resins are not used in food and beverage cans. However, phenolics are common crosslinkers (e.g. in epoxide resins) and increase their resistance.

Acrylic

Acrylic resins are most commonly synthesized from ethylacrylate. They have a clean appearance and display corrosion and sulfide stain resistance, but they are brittle and may change the taste and odor of foods.

Polyester

Isophthalic acid (IPA) and terephthalic acid (TPA) are the main carboxylic acids used in polyester coatings. Polyester resins are easy to handle during the production process and adhere well to the metal surface, but they are usually not stable under acidic conditions and have a poor corrosion resistance. Alternatively, polyethylene terephthalate (PET) coatings are used to laminate beverage cans, but adhesives are needed to bind the PET onto the metal.

Polyolefins

Coatings that are based on dispersions of polyolefins have recently entered the market. According to the manufacturer, the final polyolefin coating exhibits corrosion protection, adhesion, and flexibility without impacting the flavor of the food.

4. Regulation

U.S.

Polymeric and resinous coatings are covered under 21 CFR 175.300. This code lists permitted starting substances and specifies test conditions and migration limits. Can coatings meeting these specifications are compliant with the law. In May 2015, California’s Office of Environmental Health Hazard Assessment (OEHHA) added BPA to the list of chemicals known to cause reproductive harm under Proposition 65. Manufacturers, distributors, and retailers now have to inform the consumers of BPA-containing products with a clear and reasonable warning regarding the chemical hazards (FPF reported).

Europe

Can coatings are not regulated by an EU-wide legislation, but national measures are in place in the Netherlands, Belgium, the Czech Republic, Greece, Italy, Slovakia, France, and Spain. Harmonized regulations for specific chemicals known to migrate from can coatings exist for bisphenol A diglycidyl ether (BADGE) and its derivatives (Commission Regulation EC 1895/2005) and for inorganic tin (Commission Regulation EC 242/2004). A draft of a Commission Regulation on the use of BPA in varnishes and coatings currently suggests a specific migration limit of 0.05 mg/kg food (FPF reported). In France, the use of BPA is prohibited in FCMs including all packaging, containers and utensils intended to come into direct contact with food (LOI n° 2010-729) (FPF reported).

5. Migration, exposure & biomonitoring

Most studies investigating chemical migration from food cans focused on BPA, BADGE and their derivatives. Especially the amount of data for BPA provide a good basis for exposure estimates. However, the total migrates from cans may also contain oligomers, catalysts, reaction accelerators, epoxidized edible oils, amino resins, acrylic resins, various esters, waxes, lubricants, and metals. Furthermore, non-intentionally added substances (NIAS) such as impurities, reaction by-products and degradation products generally constitute a part of the migrate. Exposure estimates for these, often complex mixtures are much more difficult or even impossible to calculate, because many NIAS are unknown or unidentified substances.

A correlation exists between the human exposure to BPA and the consumption of canned food and, to a far lower extent, canned beverages. In 2012, a study showed that BADGE and its derivatives were detected in all test samples from the U.S. and China and that urinary concentrations exceeded those of BPA by 3 to 4 times.

6. Health effects

Can coatings generally release complex chemical mixture into the food and only few of the migrants were thoroughly tested. Extensive toxicity data exist for BPA covering many different endpoints such as reproductive and developmental effects as well as neurological, immune-modulatory, cardiovascular and metabolic effects. In 2004, BADGE was judged to not raise concern for genotoxicity, carcinogenicity, reprotoxicity and developmental toxicity. However, more recent studies indicated some effects on reprotoxic and developmental endpoints.

Many migrating substances are completely unknown, but they may strongly contribute to the toxicity of the migrate. In 2006, cytotoxic effects of migrates from epoxy- and polyester-based coatings were tested using a series of assays. The results of one of these assays showed that only about 0.5% of the cytotoxic effects measured in the migrate from epoxy coatings could be traced back to the amount of BPA, BADGE and BADGE·H2O. This example illustrates the importance of tests targeting the final migrate and not only single substances during risk assessment.

7. Selected references

Why are cans coated?

- Bomgardner MM. 2013. No clear winner in race to find non-BPA can linings. C&EN. 91:24-5.

- Regulation (EC) No 1935/2004 of the European Parliament and of the Council of 27 October 2004 on materials and articles intended to come into contact with food.

Can production and market data

- LaKind JS. 2013. Can coatings for foods and beverages: Issues and options. Int J Technol Policy Manag. 13:80-95.

- Robertson GL. 2006. Food Packaging: Principles and Practice, Second Edition. CRC Press, Boca Raton, FL, USA.

- Pegg D. 2013. “PPG Packaging Coatings – Bringing innovation to the surface.” (pdf)

- Page B, Edwards M, and May N. 2011. Metal packaging. In: Food and Beverage Packaging Technology. R. Coles and M. Kirwan, eds. Wiley Online Library. pp 107-35.

- Rexam. 2015. “Annual Report 2015.” (pdf)

- European Coatings. 2012. “Can and coil coatings have a significant market impact.”

Coatings: properties and alternatives

- LaKind JS. 2013. Can coatings for foods and beverages: Issues and options. Int J Technol Policy Manag. 13:80-95.

- Robertson GL. 2006. Food Packaging: Principles and Practice, Second Edition. CRC Press, Boca Raton, FL, USA.

- Oldring PKT, and Nehring U. 2007. Packaging materials – 7. Metal packaging for foodstuffs. ILSI Europe Report Series.1-44.

- Simal-Gandára J. 1999. Selection of can coatings for different applications. Food Rev Int. 15:121-37.

- NAMPA. 2009. “Considerations in development of can coatings technologies.” (pdf)

- Whitaker R. 2007. Metal packaging and chemical migration into food. In: Chemical Migration and Food Contact Materials. K.A. Barnes, C.R. Sinclair and D.H. Watson, eds. Woodhead Publishing Limited, Cambridge. pp 251-70.

Migration, exposure & biomonitoring

- 2015. Scientific Opinion on the risks to public health related to the presence of bisphenol A (BPA) in foodstuffs. EFSA Journal. 13:3978.

- Grob K, Spinner C, Brunner M, et al. 1999. The migration from the internal coatings of food cans; summary of the findings and call for more effective regulation of polymers in contact with foods: a review. Food Addit Contam. 16:579-90.

- Geueke B. 2013. “FPF Dossier: Bisphenol A.” Food Packaging Forum. DOI: 10.5281/zenodo.33495. (pdf)

- Geueke B. 2014. “FPF Dossier: Non-intentionally added substances.” Food Packaging Forum. DOI: 10.5281/zenodo.33514. (pdf)

- Geens T, Apelbaum TZ, Goeyens L, et al. 2010. Intake of bisphenol A from canned beverages and foods on the Belgian market. Food Addit Contam A. 27:1627-37.

- Cao XL, Corriveau J, and Popovic S. 2010. Sources of low concentrations of bisphenol A in canned beverage products. J Food Prot. 73:1548-51.

- Simoneau C, Theobald A, Hannaert P, et al. 1999. Monitoring of bisphenol-A-diglycidyl-ether (BADGE) in canned fish in oil. Food Addit Contam. 16:189-95.

- Theobald A, Simoneau C, Hannaert P, et al. 2000. Occurrence of bisphenol-F-diglycidyl ether (BFDGE) in fish canned in oil. Food Addit Contam A. 17:881-7.

- Paseiro-Cerrato R, MacMahon S, Ridge CD, et al. 2016. Identification of unknown compounds from polyester cans coatings that may potentially migrate into food or food simulants. J Chromatogr A. 1444:106-13.

- Magami SM, Oldring PK, Castle L, et al. 2015. Migration of melamine from thermally cured, amino cross-linked can coatings into an aqueous ethanol food simulant: aspects of hydrolysis, relative reactivity and migration. Food Addit Contam A. 32:403-9.

- Geens T, Aerts D, Berthot C, et al. 2012. A review of dietary and non-dietary exposure to bisphenol-A. Food Chem Toxicol. 50:3725-40.

- Vandenberg LN, Hauser R, Marcus M, et al. 2007. Human exposure to bisphenol A (BPA). Reprod Toxicol. 24:139-77.

- Wang L, Wu Y, Zhang W, et al. 2012. Widespread occurrence and distribution of bisphenol A diglycidyl ether (BADGE) and its derivatives in human urine from the United States and China. Environ Sci Technol. 46:12968-76.

Health effects

- 2015. Scientific Opinion on the risks to public health related to the presence of bisphenol A (BPA) in foodstuffs. EFSA Journal. 13:3978.

- Gao XQ, and Wang HS. 2014. Impact of bisphenol a on the cardiovascular system – epidemiological and experimental evidence and molecular mechanisms. Int J Environ Res Public Health. 11:8399-413.

- Heindel JJ, Newbold RR, Bucher JR, et al. 2015. NIEHS/FDA CLARITY-BPA research program update. Reprod Toxicol. 58:33-44.

- Khan D, and Ahmed SA. 2015. Epigenetic regulation of non-lymphoid cells by bisphenol A, a model endocrine disrupter: potential implications for immunoregulation. Front Endocrinol. 6:91.

- Le Corre L, Besnard P, and Chagnon MC. 2015. BPA, an energy balance disruptor. Crit Rev Food Sci. 55:769-77.

- Li J, Mao R, Zhou Q, et al. 2016. Exposure to bisphenol A (BPA) in Wistar rats reduces sperm quality with disruption of ERK signal pathway. Toxicol Mech Method. 26:180-8.

- Michalowicz J. 2014. Bisphenol A – Sources, toxicity and biotransformation. Environ Toxicol Phar. 37:738-58.

- Vandenberg LN. 2014. Low-dose effects of hormones and endocrine disruptors. In: Endocrine Disrupters. G. Litwack, ed. pp 129-65.

- Geueke B. 2013. “FPF Dossier: Bisphenol A.” Food Packaging Forum. DOI: 10.5281/zenodo.33495.

- Poole A, van Herwijnen P, Weideli H, et al. 2004. Review of the toxicology, human exposure and safety assessment for bisphenol A diglycidylether (BADGE). Food Addit Contam. 21:905-19.

- 2004. Opinion of the Scientific Panel on Food Additives, Flavourings, Processing Aids and Materials in Contact with Food (AFC) on a request from the Commission related to 2,2-bis(4-hydroxyphenyl)propane bis(2,3-epoxypropyl)ether (Bisphenol A diglycidyl ether, BADGE). The EFSA Journal. 86:1-40.

- Yang YJ, Lee SY, Kim KY, et al. 2010. Acute testis toxicity of bisphenol A diglycidyl ether in Sprague-Dawley rats. J Prev Med Public Health. 43:131-7.

- Chamorro-Garcia R, Kirchner S, Li X, et al. 2012. Bisphenol A diglycidyl ether induces adipogenic differentiation of multipotent stromal stem cells through a peroxisome proliferator-activated receptor gamma-independent mechanism. Environ Health Persp. 120:984-9.

- Mittag N, Förster S, Hoppe S, et al. 2006. Bioassay guided analysis of migrants from can coatings. J Verbrauch Lebensm. 1:345-53.